Workflows, efficiency, satisfaction, and profitability

I’ve been writing a lot about how Efficiency and Profits go hand in hand. That efficiency in a service department is measured by the average number of technician hours billed each day, also often referred to as first call completes. What is efficiency, and how do we achieve it? Increased efficiencies are a result of well-defined Workflow.

Consider these two Wikipedia definitions and how they intersect.

Efficiency is the ability to avoid wasting materials, energy, efforts, money, and time in doing something or in producing the desired result. In a more general sense, it is the ability to do things well, successfully, and without waste. “Efficiency is thus not a goal in itself. Wikipedia

A workflow consists of an orchestrated and repeatable pattern of activity, enabled by the systematic organization of resources into processes that transform materials, provide services, or process information. Wikipedia

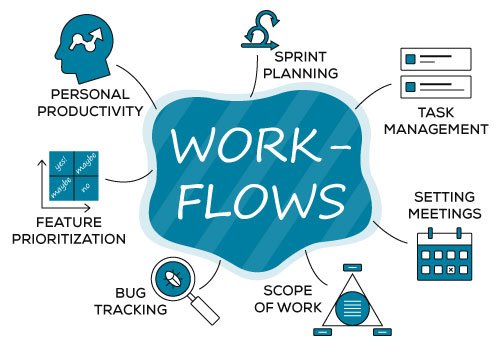

For any service operation to be efficient, it must have and follow clearly defined workflows. Workflows are planned and follow a specific series of events. They are consistently repeatable; they are reliable and involve the same staff members. It’s a good practice to document your workflows for reference and the timely onboarding of new employees. Workflows are required and impact reporting and financial results, marketing, employees, and other departments. Accurate and efficient workflows drive efficiency, customer satisfaction, and profitability.

Are your processes and workflows known? Who knows them?

When creating workflows, it is helpful to refer to your company org chart. Give each employee a list of daily, weekly, and monthly responsibilities. Educate your employees on the critical role they play in your company and its processes. Ensure all staff understands not only the how but also the why of your workflows. Generally, customer dissatisfaction and negative reviews are a direct result of someone not following a prescribed workflow.

Measure employee performance in workflows through KPIs and set goals. It is practical to measure an individual employee’s KPIs against the company average for that KPI. Doing so will highlight the weaker employees and identify where additional training is required.

Document the process, write it out step by step, making it as straightforward as possible. Test it, make adjustments and then train your staff. Create ownership and a culture of accountability in process workflows.

Efficiencies (increased billable hours in service operations) are a direct result of well thought, planned, and rehearsed workflows for every scenario in the customer’s journey through your service department, from the answered call for service to the final restitution for services rendered. You can’t assume that common sense will always prevail in your team’s decision-making process. Provide your team with a clear, concise roadmap to all your workflows.

Consider the following workflows that impact efficiencies in any service operation:

Business management software that supports and enables a paperless operation.

Mobile technology for technicians to look up parts and service literature in customers’ homes.

Technicians use smartphones to communicate with customers, capture model & serial tags and pre-existing property damage.

Technicians start their day at their first and end at their last stops avoiding the morning zoo in the office or shop.

Local courier services to send parts to technicians’ homes or drop-ship parts to customers’ homes.

Technicians provide repair estimates in the house and reschedule calls as necessary from the customer’s home, eliminating the office personnel.

Pre-diagnose calls three times before truck roll; CSR, the service manager, and the technician before going to the call. Check out MPH diagnostics.

Dispatch the right tech with the tools and required skillsets. (part of pre-diagnosis workflow)

Manage parts inventory, stock frequently used parts, and return unnecessary ones.

Consider drive times, geographic barriers, and customer time frames.

It’s not too late! Create your process, document it, and then train your staff.

Accurate and efficient workflows drive efficiency, customer satisfaction, and profitability.